PS Plate Intermittent Offset Printing Machine don IML

Bayani

A cikin filin bugawa na yau da kullun, rabon kayan buga rubutu na gargajiya yana raguwa sannu a hankali, kuma nau'ikan kayan aiki masu inganci iri-iri suna samun biyan bukatun abokan ciniki, musamman kayan IML da na'urorin buga IML.

ZoNTEN ZTJ-330 na'urar buga IML offset IML an ƙaddamar da shi a kasuwa a cikin 2010 kuma ya sayar da kayan aiki sama da 800 ya zuwa yanzu.Shi ne mafi amintaccen mai kera injin buga IMLprinting a China.

Kamfaninmu yana da jerin mafita na injin IMLprinting wanda za'a iya keɓance shi da buƙatun aiwatar da abokin ciniki.Ciki har da alamar guga, alamar cakulan, alamar yogurt da sauransu.A arewacin kasar Sin ciki har da Hebei da Shandong, ɗimbin masu amfani da aminci suna amfani da ZONTEN ZTJ-330 na'urar bugu na IML don buga kayan IML.

Ƙayyadaddun Fasaha

| Samfura | ZTJ-330 | ZTJ-520 |

| Max.Fadin Yanar Gizo | mm 330 | mm 520 |

| Max.Nisa Buga | mm 320 | mm 510 |

| Maimaita Buga | 100 ~ 350mm | 150 ~ 380 mm |

| Kauri na Substrate | 0.1 zuwa 0.3mm | 0.1 ~ 0.35mm |

| Gudun inji | 50-180rpm (50M/min) | 50 ~ 160rpm |

| Max.Cire Diamita | 700mm | 1000mm |

| Max.Maida Diamita | 700mm | 1000mm |

| Bukatun huhu | 7kg/cm² | 10kg/cm² |

| Jimlar iyawa | 30kw/6 launuka (Ba a haɗa da UV ba) | 60kw/6 launuka (Ba a haɗa da UV ba) |

| Ƙarfin UV | 4.8kw/launi | 7kw/launi |

| Ƙarfi | 3 Matakai 380V | 3 Matakai 380V |

| Gabaɗaya Girma (LxWx H) | 9500 x 1700 x 1600mm | 11880x2110x1600mm |

| Nauyin Inji | kusan 13 ton/6 launuka | kamar 15 ton/6 Launuka |

Karin Bayani

Nauyin kowane rukunin bugu shine 1500kgs.

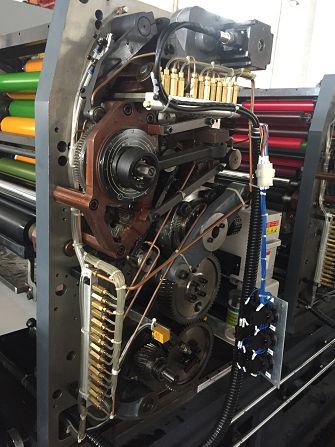

Yin amfani da ingantattun ginshiƙan helical da fuselage panels da masu samar da wutar lantarki na Shanghai Electric suka yi, gami da kauri na bango 50mm, faɗin gear helical 40mm, matsakaicin raguwar girgiza na'ura da duka.

Duk injin ɗin yana ɗaukar motar servo + helical gear (PS farantin abin nadi, abin nadi na bargo da abin abin nadi) + kayan spur (tsarin tawada mai ɗamara) + motar motsa jiki (nadi mai tawada), babu sarkar tuƙi.

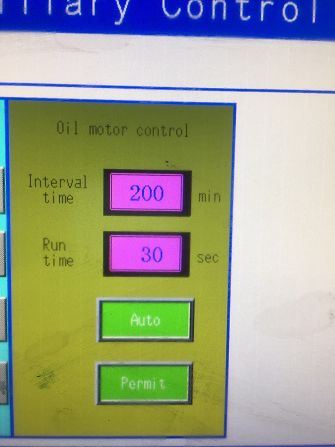

Lubrication ta atomatik: karɓi jujjuyawar mai, kowane mai yana amfani da lokaci ɗaya; kowane maki mai, adadin da ake buƙata na daidaitaccen iko, lokacin cikawa don saita daidai, don tabbatar da cewa kayan aikin suna aiki daidai da rayuwa.

Ana sarrafa sarrafa motsi na naúrar ta hanyar injin servo don tabbatar da daidaiton motsi.